-

1

Industrial alkaline protease

Industrial Alkaline Protease

Product description

Alkaline protease is a high yielding strain of Bacillus licheniformis, which is extracted and refined by deep liquid fermentation. Alkaline protease, also known as serine protease, is a serine endonuclease. Industrial alkaline protease is specific and has a strong ability to hydrolyze protein molecular peptide chains. It also has the function of hydrolyzing amide bond, ester bond, achieving ester and peptide transformation. It is widely used in feed, leather, silk, food, medical, brewing and other industries.

Product characteristic

1、 Temperature area:Effective hydrolysis temperature range 20-60℃,Optimum enzymatic hydrolysis temperature range 35-45℃.

2、 PH range:Effective hydrolysis PH range 4-11,Optimum enzymatic hydrolysis ph range 9-11.

Product specification and property

Powder product specification:Yellowish brown powder

Powder product specification:100 thousand U/g、200 thousand U/g、300 thousand U/g

Liquid product:Light brown or reddish brown liquid

Liquid product specification:100 thousand U/ml、200 thousand U/ml

Product executive standard

Product executes GB/23527-2009

Enzymatic properties

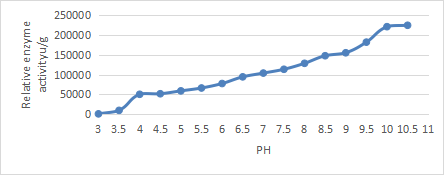

1)Effects of different pH conditions on the activity of alkaline protease

P1 Effect of PH value on activity of alkaline protease

As seen from Figure 1, the optimal pH of alkaline protease is 10.5. It has high enzyme activity characteristics in the range of pH10-10.5

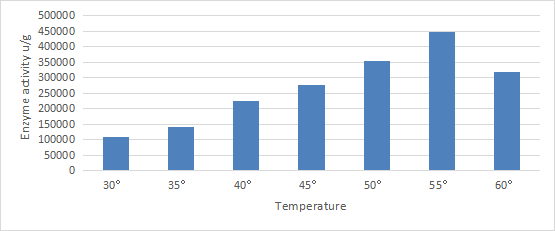

2)Effect of temperature on the activity of alkaline protease

P2 Effect of temperature on the activity of alkaline protease

As seen from Figure 2, the enzyme activity can still retain a high level at 60℃ after 15-20min treatment at 45℃-60℃, which indicates that the product has excellent stability at high temperature.

Product application

1、 Feed

(1)Decompose feed protein into amino acids. It is beneficial to the absorption and utilization of protein by livestock and poultry.

(2)Supplement animal endogenous enzyme deficiency. Enhance appetite and promote animal growth and development.

(3)Increase the utilization rate of feed nutrients and improve the production performance.

2、Washing

(1)It can hydrolyze protein peptide bond and effectively remove blood stains, sweat stains, milk stains, oil stains and other protein stains.

(2)Because the alkaline protease is suitable for pH range 7-12. Optimum temperature range 25-60℃. It is suitable for a variety of washing conditions.

3、Leather making

(1)Remove non-fibrous protein from raw material skin to make the leather soft.

(2)Used for leather depilation. Make the grain surface clear and no damage. The pores are fine and smooth, improving the brightness of the skin texture and various properties of the finished leather.

4、Protein extraction

(1) The production of yeast extract: the protein in hydrolyzed yeast is converted into amino acids, which has strong taste and improves the yield and production efficiency.

(2)Soybean polypeptide and soybean phospholipid production: Improve the solubility and function of soybean protein and improve the nutritional value.

(3)Modified protein production: Improve product stability, dispersibility and emulsibility. Improve product application range.

(4)Production of fish collagen: hydrolyze fish. Improve the yield. No bitterness.

5、Silk scouring

The sericin in raw silk is hydrolyzed to reduce the damage of silk and improve the quality of silk.

6、Chondroitin, heparin sodium extraction

Alkaline protease for Chondroitin: The yield and purity of chondroitin sulfate can be effectively improved by hydrolysis of various animal cartilage at a certain temperature and pH value to degrade proteins.

Alkaline protease for Heparin:At a certain temperature and PH value, the crude protein of small intestinal mucosal fluid can be hydrolyzed without odor, which can effectively improve the yield and purity of heparin sodium.

|

Usage |

Usage of 100 thousand Enzyme activity |

Recommended usage |

|

Chondroitin extraction |

0.1-1% |

Add raw material per ton 1-10kg Enzyme |

|

Heparin extraction |

0.1-1% |

Add raw material per ton 1-10kg Enzyme |

|

Silk scouring |

0.05-0.5% |

Add raw material per ton 0.5-5kg Enzyme |

|

Hair removal of leather |

0.05-0.5% |

Add raw material per ton 0.5-5kg Enzyme |

|

Tannery waste disposal |

0.05-0.5% |

Add raw material per ton 0.5-5kg Enzyme |

|

Recipe of detergent |

0.05-0.5% |

Add raw material per ton 0.5-5kg Enzyme |

|

Amino acid water soluble fertilizer production |

0.1-1% |

Add raw material per ton 1-10kg Enzyme |

|

Industrial gelatin production |

0.1-1% |

Add raw material per ton 1-10kg Enzyme |

|

Protein extraction |

0.1-1% |

Add raw material per ton 1-10kg Enzyme |

|

Feed |

0.1-1% |

Add raw material per ton 1-10kg Enzyme |

Product Safety

Enzymes are protein substances. For sensitive people, inhaling enzyme powder or fogdrop may cause allergic reactions. Prolonged exposure may irritate the skin, eyes and mucous membranes. It is recommended to wear a mask during operation. Avoid inhaling the enzyme dust. If the product is accidentally splashed on the skin or eyes, please rinse immediately with water.

Caution

After opening the bag or bucket, please tie the bag mouth or tighten the bucket lid to avoid inactivation of active ingredients if not used up at each time.

Packing and storage

1. Packing:2kg/bag(bucket);20kg/bag(bucket)

2. This product is an active biological agent. In transport and storage process, please avoid light, keep low temperature, dry and ventilation.

3. The shelf life of product is 12 months in a cool and dry environment.

Related products:

Hits:1663 Entry time:2023-01-09 20:24:10【Print this page】【return】