-

1

Cellulase for feed

Cellulase, a single enzyme preparation for feeding, which is fermented by advanced deep liquid technology and processed by unique post-treatment technology. It acts on cellulose, which is widely found in plant’s feed materials, improving the digestibility of feed nutrient and promoting animal production performance.

Why we use cellulase

The anti - nutritional effect of non-starch polysaccharide (NSP) in feed is well known by us. The main reason for the low nutrient utilization of some plant materials is the high proportion of NSP, including xylan, β -glucan, cellulose, mannan, pectin and so on. Cellulose has always been the main component of NSP in common plant feed materials.

Table 1 Cellulose content and proportion of total NSP in commonly used plant feed materials

|

Plant feed materials |

Cellulose content (%) |

Proportion of total NSP (%) |

|

Corn |

2 |

25 |

|

Wheat |

2 |

17.4 |

|

Barley |

3.2 |

19 |

|

Sorghum |

2.2 |

45.8 |

|

Wheat bran |

10.7 |

30.1 |

|

Wheat middlings |

8 |

30.5 |

|

Rice bran |

9.74 |

50.1 |

|

Soybean meal |

6 |

20.5 |

|

Cottonseed meal |

6 |

24.6 |

|

Rapeseed meal |

8 |

27.3 |

|

Sun flower seed meal |

18 |

44.4 |

The anti-nutritional effects of cellulose have been proved to be as follows: shielding nutrients, inhibiting digestive enzyme activity, increasing chyme viscosity, reducing available feed energy, inhibiting fat digestion and absorption, and causing intestinal pathogens to propagate, etc.

〔Cellulase function〕

![]() Degrade cellulose Effectively, reduce chyme viscosity, release energy, protein, amino acid and other nutrients, improve nutrient digestibility.

Degrade cellulose Effectively, reduce chyme viscosity, release energy, protein, amino acid and other nutrients, improve nutrient digestibility.

![]() Improve feed quality, increase animal daily gain, egg production rate and feed efficiency.

Improve feed quality, increase animal daily gain, egg production rate and feed efficiency.

![]() Reduce feed cost while maintaining the same performance of feed products.

Reduce feed cost while maintaining the same performance of feed products.

![]() Reduce the difference of different batches of raw materials and stabilize feed quality.

Reduce the difference of different batches of raw materials and stabilize feed quality.

![]() Improve intestinal micro-ecology, balance intestinal flora, improve animal’s disease resistance.

Improve intestinal micro-ecology, balance intestinal flora, improve animal’s disease resistance.

![]() Reduce fecal nitrogen excretion, improve barn air quality, reduce environmental pollution.

Reduce fecal nitrogen excretion, improve barn air quality, reduce environmental pollution.

〔Cellulase features〕

![]() Combination of highly active intraconuclease and exonuclease cellulase

Combination of highly active intraconuclease and exonuclease cellulase

The complex enzyme system is composed of three enzymes (C1 enzyme, CX enzyme and BG enzyme) ,which greatly improves the degradation rate of dietary cellulose, as shown in Fig.1.

Fig.1 Cellulase enzymolysis mode

![]() Good synergy

Good synergy

Cellulase has good synergism with other non-starch polysaccharide enzymes, which can effectively promote the degradation of dietary "crude fiber substances" and improve the release and utilization of nutrients.

![]() Unique fermented strain

Unique fermented strain

Unique strain, R&D gathered with famous scientific research institute, is high efficiency.

![]() Advanced production technology

Advanced production technology

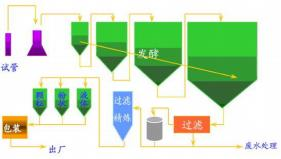

Deep liquid fermentation technology with unique downstream process; Make sure the high quality and high stability with ISO9001, ISO220000 and EU FAMI-QS quality assurance system and 5S management strandards.

Fig.2 Cellulase production flat

![]() Wide range of PH

Wide range of PH

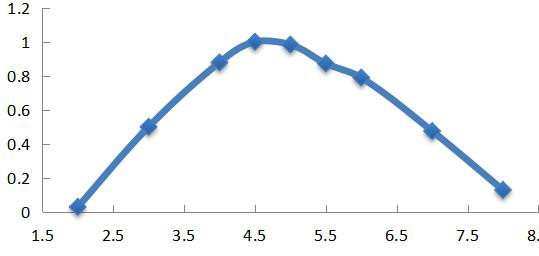

When the pH is between 2.5 and 7.5, it is consistent with the physiological pH range of the intestinal tract of animals, with a wide range of action and a longer time. Cellulase had the highest activity at pH5.0 (Fig. 3). It is mainly in the small intestine, which has a longer duration of action. Cellulase’s activity is increased gradually when digesta is moved backward in animal digestive tract.

|

Fig. 3 Cellulase activity changes with pH

![]() Good temperature resistance

Good temperature resistance

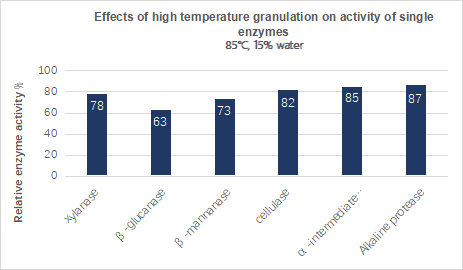

The optimum fermentation strain ensures high temperature resistance of cellulase (Fig. 4).

FIG. 4 Effects of high temperature granulation on activity of single enzymes

![]() High resistance to endogenous protease

High resistance to endogenous protease

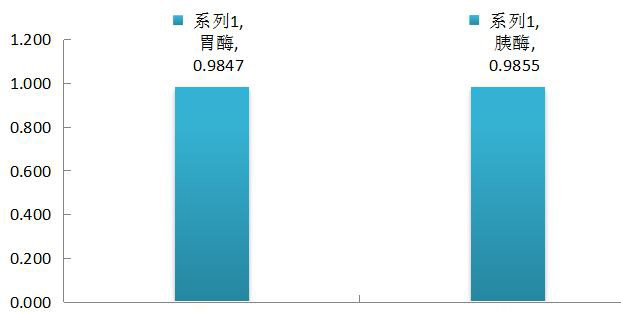

Enzyme is a protein that can be partially digested by endogenous protease. Cellulase takes this into full consideration in the screening of fermentation strains and has strong resistance to endogenous protease (FIG. 5).

|

Gastric enzyme Pancreatic enzyme

Fig. 5 Changes of cellulase activity in animal digestive tract

![]() Insensitive to inhibitors

Insensitive to inhibitors

Inhibitors in feed can reduce cellulase activity. The sensitivity of inhibitors is an important index to measure the enzyme quality. Cellulase is relatively insensitive to inhibitors, ensuring greater activity.

〔Product specification and usage〕

![]() Product specification Powder:4000 16000U/g;

Product specification Powder:4000 16000U/g;

Reminder: Enzyme activity in the market is not uniform. Each "IU" represents different meaning. The activity definition of Spiite cellulase refers to the national standard NY/T 912-2020 of the Ministry of Agriculture. The actual activity of per unit cellulase activity is much higher than most similar products in the market.

Department of Agriculture NY/T 912-2020 Cellulase activity is defined as:

At PH5.5 and 37℃, the amount of enzyme required to produce 1μmol of reducing sugar from 7.5mg/ml sodium carboxymethyl cellulose substrate solution per minute is one enzyme activity unit (U).

![]() Usage

Usage

Cellulase can be used alone or combined with other enzymes, which is depending on feed composition and purpose. The following are the methods used alone (16000 U/g product as an example, Table 2) :

Table 2 Application methods of cellulase in full-price compound feed

Method 1: To improve product quality

Method 2: To reduce feed costs

Direct addition of 12 to 25g per ton of complete feed. Feed formula is not adjusted.

The additive amount of enzyme is the same as method 1.

u Complex method: reduce the design of digestive energy or metabolic energy of full price formula feed

The standard is 30kcal / kg, which is reset by adjusting the proportion of energy feed and carrier

Calculate the formula.

u Simple method: in the full price formula feed, 1% corn is used to replace it directly 1% oil, and the proportion of other raw materials remains unchanged.

〔Product selection recommendations〕Note: Powdery enzymes need to be mixed at least twice in feed processing. They can be pre-mixed with vitamins and other trace components first. Then they will be mixed with other feeds.

![]() Powder and granulating temperature less than 85 ℃ of granular material choose powder enzyme; It is recommended to use liquid enzyme after spraying for granular with granulation temperature higher than 85℃.

Powder and granulating temperature less than 85 ℃ of granular material choose powder enzyme; It is recommended to use liquid enzyme after spraying for granular with granulation temperature higher than 85℃.

![]() If there is no post-spraying equipment and cellulase needs to be used in granulating above 85℃, it is suggested to add an additional 20% to 50% safety margin to ensure the full action of product performance.

If there is no post-spraying equipment and cellulase needs to be used in granulating above 85℃, it is suggested to add an additional 20% to 50% safety margin to ensure the full action of product performance.

![]() Cellulase is not recommended to be added to diets of young animals and barley alone. But it should be used in combination with other enzymes.

Cellulase is not recommended to be added to diets of young animals and barley alone. But it should be used in combination with other enzymes.

〔Packing, transportation and storage〕

![]() Packing: The powder enzyme is packed in 20kg kraft paper bag.

Packing: The powder enzyme is packed in 20kg kraft paper bag.

![]() Transportation: Protected from sun exposure and rain; Shall not be mixed with toxic and harmful and pollutants;

Transportation: Protected from sun exposure and rain; Shall not be mixed with toxic and harmful and pollutants;

![]() Storage: Stored in a cool, ventilated and dry room, and the shelf life of powder enzyme is 12 months.

Storage: Stored in a cool, ventilated and dry room, and the shelf life of powder enzyme is 12 months.

Related products:

Hits:1474 Entry time:2023-01-09 21:11:30【Print this page】【return】